Condition Based Monitoring

Condition Based Monitoring

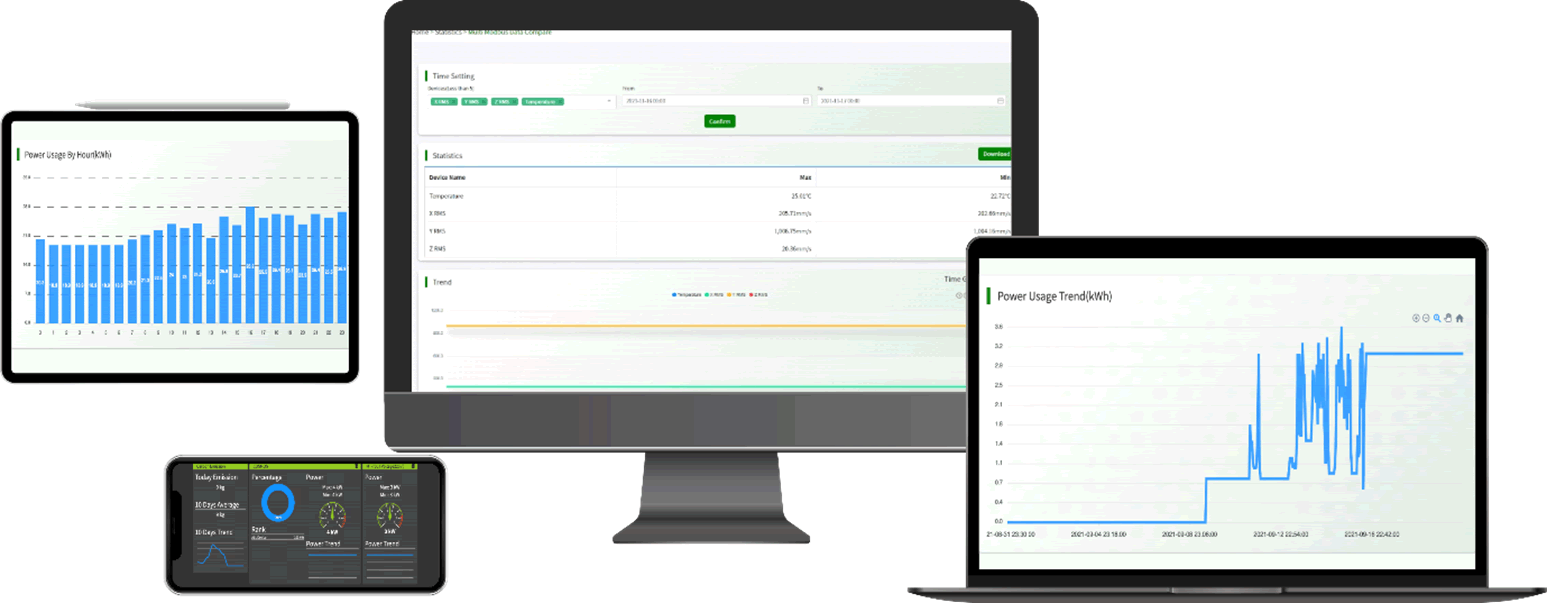

The condition-based monitoring system works through sensors that detect noise and vibrations in the machine. Integrate our Cosmos digiCBM and create a smart ecosystem that will allow you to:

- Monitor: temperature, vibration, pH level, oil level, carbon emission, power and energy, current and voltage, etc.

- Receive automatic escalation notifications from machines.

- Keep track of machine-operating costs.

- Use data to improve spare part management.

Unscheduled terminations and faults in production can be bypassusing the Cosmos digiCBM multi-functional condition monitoring detectors. These intelligent sensors supply condition data that you can utilize to automate manual examinations. This condition information is valuable for the element of IIoT implementing smart and flexible manufacturing. You can easily connect it via the IO module and the LAN.

THE BENEFITS:

- Minimizes accidental failure risk and increases the reliability of the assets.

- Provide a real-time alert when specific thresholds exceeded.

- Real-time monitoring of an asset’s health decreases maintenance costs by scheduling servicing based on the asset's current fitness.

- Improve manufacturing throughput by decreasing maintenance downtime and unexpected asset downtime.

- Real-time monitoring of assets extends their lifetime by ensuring they are used within the manufacturer’s specifications.